|

|

|

|

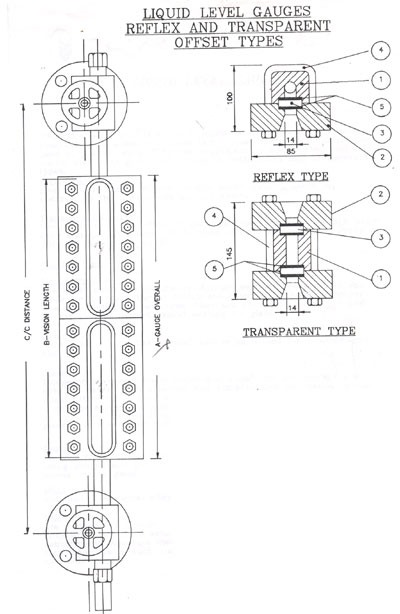

LIQUID LEVEL GAUGES REFLEX AND TRANSPARENT OFFSET TYPES |

|

|

|

"

CRISTAL" offers tubular type liquid level gauge

glasses for accurate

observation of levels in process tanks, stills or any

liquid container used

in process work. Thery are rugged, simply constructed

and efficient. Flat

glass gauges are made in both Reflex and Transparent

types.

Reflex Gauges:

give a clean line of separation, with liquid

showing black in contrast to

the mirror-like surface above.

Transparent Gauges:

Levels, colour and interface of the liquid can be noted

through heavy

duty transparent glasses. Both types are made in

pressure group

upto 250 kg/cm2 @ 400 C

Construction :-

Liquid Chamber :

The liquid chambers (Single or Multiple section)

are made in one piece

from a solid bar of C.S, S.S. etc. having high physical

properties at

elevated temperatures. They are accurately machined and

ground to

give perfect gasket seating for glass.

Cover:

Made from a solid bar of steel and is jig drilled

for interchange ability.

Glass :

Tempered glass,chemically stable and absolutely

transparent, is suitable

for use at high pressure and temperatures and resist to

chemical attack

of all fluid except hydrofluoric acid and caustic

solutions. For steam and

alkaline fluids mica shields are recommened as

protection to give longer

life to transparent glasses, Reflex glasses have

perfectly molded

reflecting prisms.

Gaskets :

Die-cut from highest quality material best suited

for use with liquid being

gauged and guaranteed perfect seal and absence of

mechanical stress

on the glass.

Bolts & Nuts:

are made off special alloy steels.

Valves :

are designed to provide long trouble free service

at economical cost

They are made from solid bar of different material to

meet specific

requirement. Accurate machine work throught is adopted.

Their design

incorporated such quality features as stainless steel

stem, seats and ball

checks.

Union gauge Connections :

Are provided along with valves, which allow a top

and bottom connected

gauge to be turned to any desired angle for convenient

visibility. It also

makes the liquid from the vessel-a feature which saves

times when

gauge must be cleaned or maintained.

Safety Shut-off :

Valve are provided with a

stainless steel ball check which

instantaneously shut off flow of medium in case of

gauge glass

breakage or failure of gasket.

Both Reflex and Transparent gauges are available with

endside

and back connection and they are made 'in-line' and '

offset'

wih the type of connection to fit your need.

Our standard connection is 1/2" or 3/4" NPT (male)

screwed.

Special Function Gauges :-

1. Non-frosting Gauges :-

They are made in both reflex and

transparent types of unobstructed liquid level readings of low

temperature fluids. A special frost-preventing unit projects beyond

the cover bolts so frost cannot build up across the vision slot in the

cover.

2. Large Chamber Gauges :

They are used

under unusual conditions

such as where the liquids having solids in suspension.

The gauges will

become an integral part of the vessel.

3. Welding Pad Gauges :

This type is recommended for

reading the

levels of liquids having solids in suspension. The

gauges will become an

integral part of the vessel.

Heated Gauges :

This applicable when

working with liquids which must

be kept at higher than ambient temperatures for process

reasons or to

hasten the speed of response to level changes. They are

also ised to

prevent breakage of gauges through freezing in winter.

These gauges

may be heated with steam or liquid, or may be

electrically heated.

|

|

|